We are a different and better travertine cleaning company in that we have developed Proven superior cleaning, polishing and sealing products & methods far superior to our competitors. We are the top volume travertine and natural stone finisher in the state of Arizona proven with our hard earned reviews and top customer satisfaction. Our expertise in travertine cleaning, sealing, polishing & “honing” will provide the best results for all your travertine surfaces.

Our proven custom Abrasive Process beats the standard travertine honing process provided by other stone-floor-care services: The Power Clean System has been specifically designed for Travertine. We don’t rely on just the standard materials and methods that our competitors use. We’ve tested standard abrasives, powders, and tools that are readily available for Marble. We found that just because it says on the label it works for Marble doesn’t mean it will produce a good result for travertine. Our focus has always been to develop the safest system for travertine specific characteristics.

Travertine Owners Like You Have Made Us #1 in Arizona by Choosing Baker’s More Often Than any of Our Competitors.

Travertine Density — Proper Finishing Reduces Porosity

Travertine is very similar to a sponge in that it is like a stack of bubbles. The density of the stone depends on how much stone versus the number of air pockets. Our custom abrasiveA substance used to sand, scour, scrub, smooth or polish by removal of the original material. The amount of material removed is determined by the size of the abrasive particles used (ie: grit) Sandpaper, scouring powders and steel wool are examples of abrasives. More process is able to smooth the surface of the stone which reduces surface area.

Our system is able to finish the stone without opening up air pockets underneath the surface. If you look at the surface of the travertine tile under a microscope it would look like a crystalline forest. All of these little trees are like straws that can provide millions of tiny pathways into the stone. We are actually sealing off the stone during the finishing process by reducing the surface area.

Our system is able to finish the stone without opening up air pockets underneath the surface. If you look at the surface of the travertine tile under a microscope it would look like a crystalline forest. All of these little trees are like straws that can provide millions of tiny pathways into the stone. We are actually sealing off the stone during the finishing process by reducing the surface area.

Less surface area means fewer pores. Our custom abrasiveA substance used to sand, scour, scrub, smooth or polish by removal of the original material. The amount of material removed is determined by the size of the abrasive particles used (ie: grit) Sandpaper, scouring powders and steel wool are examples of abrasives. More process starts this sealing process by closing off the pathways liquids have to get into the stone. As finishing progresses, the stone becomes more reflective. As a stone becomes more reflective it is being closed off by the reduction of surface area.

TRAVERTINE TILE CLEANING

Using custom abrasives, we wet sand the stone to loosen up surface dirt and remove loose grime and dirt accumulated in the grout lines, open pits, and fill areas. This creates a slurry that is vacuumed back up with a powerful truck mounted machine.

The use of hot water extraction at 1200psi or more provides the most effective cleaning method for your stone. Mops, buckets, and shop vacs cannot come close to the cleaning power of a truck mounted machine.

Effective and thorough cleaning is crucial for a smooth looking uniform finish and proper sealing.

Check out our videos & photos below to see our travertine cleaning and polishing process at work.

Foamy slurry created during abrasiveA substance used to sand, scour, scrub, smooth or polish by removal of the original material. The amount of material removed is determined by the size of the abrasive particles used (ie: grit) Sandpaper, scouring powders and steel wool are examples of abrasives. More processes. The slurry is removed with a high-powered truck mounted vacuum system. By far, the most effective clean up method. Shopvacs and mops/buckets cannot compare!

Our cleaning tool pulling out dirt and grime collected in the pits of the Travertine and the grout lines revealing a much cleaner and brighter floor.

Our cleaning tools are another example of how our millions of square feet of experience over many years have become a custom-manufactured advantage for our travertine cleaning and sealing process.

Satin Finish for Travertine

The Satin FinishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More is the lowest shine recommended. We really don’t recommend duller finishes, since less shine equals more porosity. Satin FinishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More is practical and what a travertine floor needs so it can be maintained properly. With the custom abrasiveA substance used to sand, scour, scrub, smooth or polish by removal of the original material. The amount of material removed is determined by the size of the abrasive particles used (ie: grit) Sandpaper, scouring powders and steel wool are examples of abrasives. More processes, the goal is the reduction of porosity. We do this with one of several different gentle but extremely effective microfine sanding processes.

Standard honingWebster says: "the process of sharpening something", such as a tool or skills. In the stone finishing industry, honing has as many different meanings as there are stone finishers honing stone. The finisher may refer to it as a procedure, the tile retailer may refer to it as a look or shine of the stone. The term has become too diluted and over-used to provide and accurate description. We don’t like the term and believe our “Custom Abrasive Process” is far more descriptive as a procedure fo... More processes such as diamond pads, sanding screens and powders will actually open up the stone, making cleaning tougher and reducing the ability of the penetrating sealer to keep water from eroding the stone over the course of time.

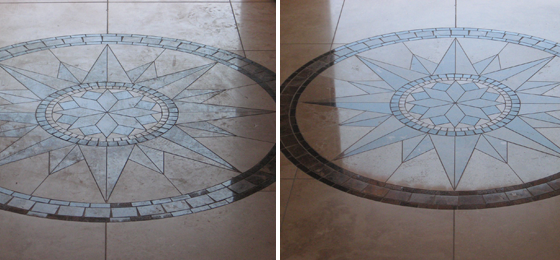

Before and After of Satin FinishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More on Travertine

Before and After of Satin FinishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More on Travertine in high-traffic area

Light Polish Finish for Travertine

Our newest option, Light PolishUsing abrasives to make the stone surface so smooth that it reflects light that results in a clear shine. More Finish, is a happy compromise between the Satin FinishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More and High PolishUsing abrasives to make the stone surface so smooth that it reflects light that results in a clear shine. More.

For those who want a bit more “pop” than our Satin FinishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More but not the formality of our High PolishUsing abrasives to make the stone surface so smooth that it reflects light that results in a clear shine. More. We will introduce chemical abrasives along with the physical abrasives to achieve our Light PolishUsing abrasives to make the stone surface so smooth that it reflects light that results in a clear shine. More Finish. Chemical abrasiveA substance used to sand, scour, scrub, smooth or polish by removal of the original material. The amount of material removed is determined by the size of the abrasive particles used (ie: grit) Sandpaper, scouring powders and steel wool are examples of abrasives. More processes break a small amount of the surface up into solution and then re-crystallizes it. Chemical processes remove air bubbles and acidic salts while increasing density. Fewer pores mean more shine and easier cleaning. The smoother the surface it is the easier it is to clean.

This sounds like crystallization, but it is not. For more information on the difference between crystallization and natural polishing click here.

SEALING TRAVERTINE TILE

We specially formulate our sealers depending on the stone we’re working on. The polymers that actually penetrate the stone are dissolved in the solvent. When applied to the stone, the solution soaks in and fills up pores and binds to the molecules of the stone to make them less susceptible to etchingWhen an acidic solution comes in contact with the stone, a dull spot is the result. The acid “eats” the stone leaving dullness, or etching behind. Penetrating sealers help to reduce severity of etches, but cannot eliminate them. Depending on acidity, some liquids can etch immediately, such as wine, where milder acidic solutions may not etch with proper penetrating sealing. More. Travertine is mostly calcite which at one point has been dissolved by water and redeposited through evaporation.

The stone also will often contain acidic salts that were in the water that deposited the travertine. The most important job of a penetrating sealer is to keep water and acidic spillsWill cause etching on the stone surface resulting in a dull spot. Acids dissolve tiny particles of stone. from eating up the stone. If too much water is used and then left on the surface of the stone during cleaning the sealer will slow it down but it will still have a very corrosive effect over time.

It is important to know that while penetrating sealers (whether ours or another brand) are helpful, they are not etch-proof or water-proof. They lessen the severity of etches and slow water absorption, but do not eliminate it.

COMMON PENETRATING SEALER MYTHS

Many homeowners assume that if their travertine, marble or limestone looks dull and dingy, it needs to be sealed and then it will be pretty again. The fact is that penetrating sealers are invisible, as they soak into the stone and have no visual effect on the stone.

It is all the custom abrasives steps used in the Cleaning and Finishing steps that come before sealing that has all the visual impact. By expertly refining the actual surface of your travertine, marble or limestone, it brings out the true beauty in a clean finish.

While sealing is an important part of our service it is not the most important part. In fact, penetrating sealers are not needed with our PolishUsing abrasives to make the stone surface so smooth that it reflects light that results in a clear shine. More finishes as our polishUsing abrasives to make the stone surface so smooth that it reflects light that results in a clear shine. More process has so refined the surface penetrating sealer can’t even soak in! This proves that proper finishing is more effective than just sealing. With our Satin finishA low luster glow for Travertine or Limestone. Reflections from overhead lighting and outside light sources are a soft glow. This finish provides a clean even sheen. More, the surface is less shiny therefore less refined so we will follow up with our high grade penetrating sealer for added protection.

EtchingWhen an acidic solution comes in contact with the stone, a dull spot is the result. The acid “eats” the stone leaving dullness, or etching behind. Penetrating sealers help to reduce severity of etches, but cannot eliminate them. Depending on acidity, some liquids can etch immediately, such as wine, where milder acidic solutions may not etch with proper penetrating sealing. More will still happen from acidic spillsWill cause etching on the stone surface resulting in a dull spot. Acids dissolve tiny particles of stone. on travertine or marble. A polished surface will lessen the severity and depth of an etch. Use of penetrating sealers will also slow acidic spill absorption, but cannot prevent it.

Travertine Photo Galleries

Our focus has always been to provide the best service, using the best tools, at a fair price, and always with honor and honesty.

Baker’s Travertine Power Clean has proudly been in business since 1988. Starting out in carpet cleaning, we evolved into tile cleaning/repair and then transitioned into Travertine and natural stone finishing. Not satisfied with the standard and available products and tools to finish marble and almost nothing available specifically for Travertine, we researched and developed our own unique abrasiveA substance used to sand, scour, scrub, smooth or polish by removal of the original material. The amount of material removed is determined by the size of the abrasive particles used (ie: grit) Sandpaper, scouring powders and steel wool are examples of abrasives. More system. Our system and powerful quality equipment provides great results in sometimes less than half the time than our top competitors.

WHY CHOOSE US

When It Comes To Natural Stone Care, We Are The Best in Arizona.

INDUSTRY LEADERS

In Business Since 1988 With

Millions of Square Feet of Happy Customers

WE STAND BEHIND OUR WORK

Bakers have always and will always make sure you’re 100% satisfied in their work. Guaranteed.

OUR TEAM SETS THE STANDARD

Mentioned by Name in Over 400 Positive Reviews, Our Employees are the Best Equipped & Experienced in the World.